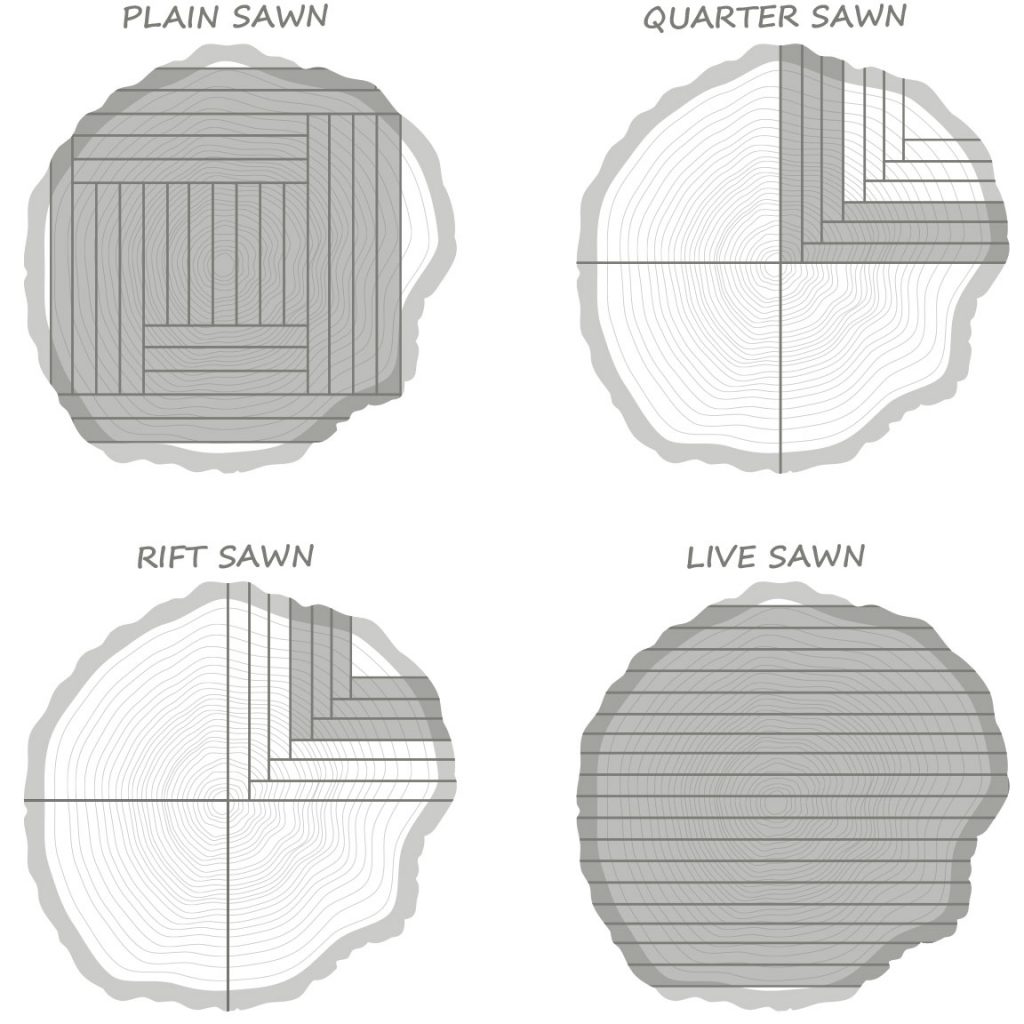

There are four different cuts of log that can be used to make hardwood flooring. Each type of cut produces unique aesthetic qualities portrayed in the floorboards. The cuts also vary in price point and can affect the overall durability of the flooring.

Plain Sawn

Plain sawn milled wood is the most popularly used cut in the flooring industry. It is a fairly efficient method of milling and helps accentuate the grain patterns within the wood. The angles of the growth rings cut by plain sawn milling usually range from 0 to 35 degrees. Also referred to as flat sawn, plain sawn lumber is produced by cutting through the wood in a sequence of parallel lines.

The Benefits of Plain Sawn Wood

Due to the cost efficiency of the milling process, the hardwood flooring it produces are extremely affordable. The 35 degree or less growth ring cuts also lead to stunning “cathedral” shaped patterns.

Quarter Sawn

Quarter sawn wood is cut where the growth rings intersect the face of the lumber at around 45 to 90-degree angles; this tends to produce relatively narrow planks. Quarter sawn cuts produce straight grain patterns with unique flecking apparent throughout.

The Benefits of Quarter Sawn Wood

Quarter sawn lumber possesses increased stability and moisture resistance. This cut is also less prone to cupping and warping so the hardwood flooring produced usually won’t require as much maintenance as some other cuts.

Rift Sawn

Rift sawing is the least used milling method out of the four different cuts; however, this is not due to a lack of quality, but the additional time and labor it requires. This puts rift sawn wood at a higher price point than the rest. Rift sawn wood is cut perpendicular to the growth rings at around 30 to 60-degree angles toward the face.

The Benefits of Rift Sawn Wood

- High dimensional stability

- Consistent, linear visual aesthetics

- Ideal for complementing quarter sawn flooring

Live Sawn

Live sawn milling combines many of the traits produced by the rift sawn, quarter sawn, and plain sawn milling processes. After the log is cut evenly to its center, parallel cuts are made which produces wider planks. Live sawn wood contains a wide array of growth ring angles since the cuts range from 0 all the way up to 90 degrees.

The Benefits of Live Sawn Wood

As one of the newest methods of milling, live sawing is extremely efficient and uses the entirety of the log. Live sawn floors are durable and tend to have a noticeably long lifespan. Because the whole log is used, live sawn flooring is also an eco-friendly choice. There is virtually no gapping between live sawn floor planks, so there are no nooks and crannies for dirt or other particles to nestle into.

A Cut Above the Rest

When deciding on the cut of wood to use for your hardwood flooring, the right choice is the one best tailored to your flooring project. With over 75 years of experience, the hardwood flooring experts at E_M Custom Flooring & Installations can help you find the right cut of wood for your project.